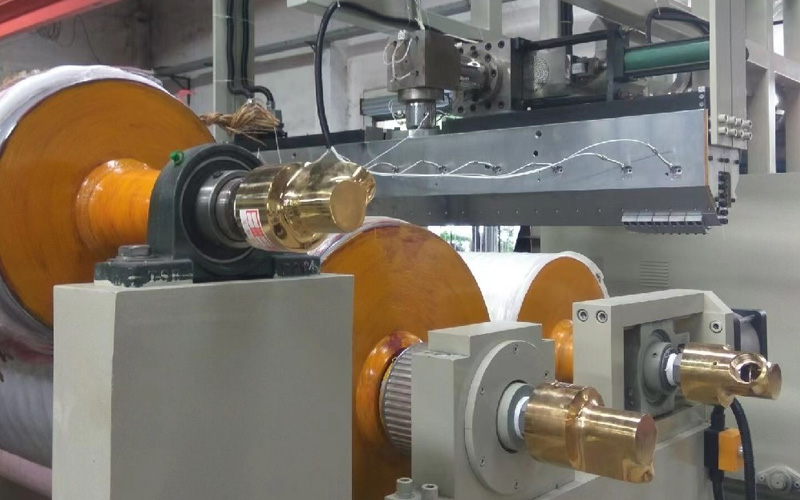

The film material is spread on the moving steel belt through the precise mould, the steel belt carries the material through the furnace body with the precise temperature control, the moisture on the material body is gradually evaporated and pumped out with the hot gas, finally, at the bottom of the feeding end, the finished film is rolled up. ...