Scope:

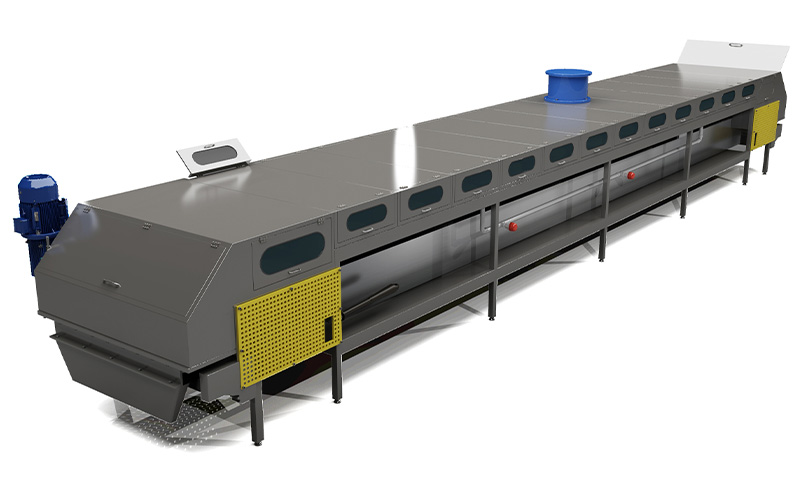

Material Requirements: RS-DB series double steel strip bonding machine is suitable for high temperature, high melting point, high viscosity materials, typical application resin fast cooling curing, high yield, the highest output of 10 tons per hour.

Typical application:

Resin industry, polyester resin, epoxy resin, rosin resin, ink resin, Phenol formaldehyde resin, etc. .

Key benefits:

◆ Rapid curing reduces contact time with air and prevents discoloration of materials.

◆ High Output, shorten production cycle

◆ Less dust, improve the production environment.

◆ Uniform product is favorable for terminal metering.

◆ Reasonable and compact structure, easy maintenance, continuous operation and improve production efficiency.

How it works:

The liquid material flows through the heat-mixing pipe into the distributing device (overflow trough) at the front of the equipment, and continuously overflows from the overflow trough, uninterruptedly and evenly distributed between the moving two layers of steel strips. The material is uniformly cooled by cooling water between the upper and lower steel strips, and the liquid material is solidified into solid material sheets with the excellent heat transfer characteristics of the steel strips. The solidified product is scraped off the steel strip by the blanking scraper, then crushed by the crusher, and collected directly into the packing procedure. The machine will adopt PLC centralized control, with speed, level, motor thermal protection, upstream and downstream chain and other protection functions, high degree of automation. Dangerous vulnerable areas are equipped with safety protection devices, equipped with electrical safety interlock switches or emergency parking devices, good safety performance. Cooling water does not come into direct contact with materials in the film-forming machine, and the product is neither contaminated nor changed in composition. Because the cooling water is not polluted, it can be reused or discharged directly, so it will not pollute the environment.

Steel strip bonding machine